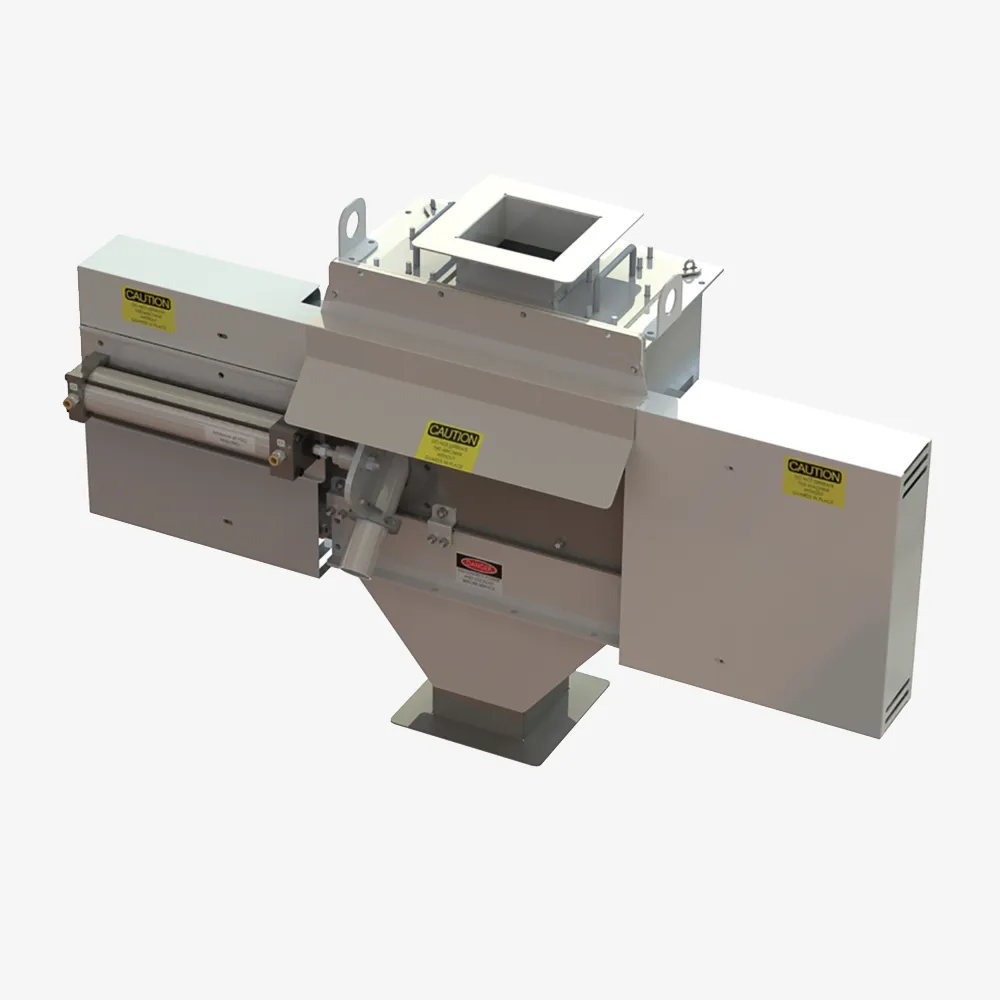

Sampling System

Sentry Sampling System

Sentry process sampling systems enable you to have controlled real time data to monitor your process. With this you can make a careful analysis of your quality which is so important in modern processing. By effectively conditioning, sampling and measuring gas, steam, liquid, slurry, powder solids or water within your production environments, you can control your process with confidence.

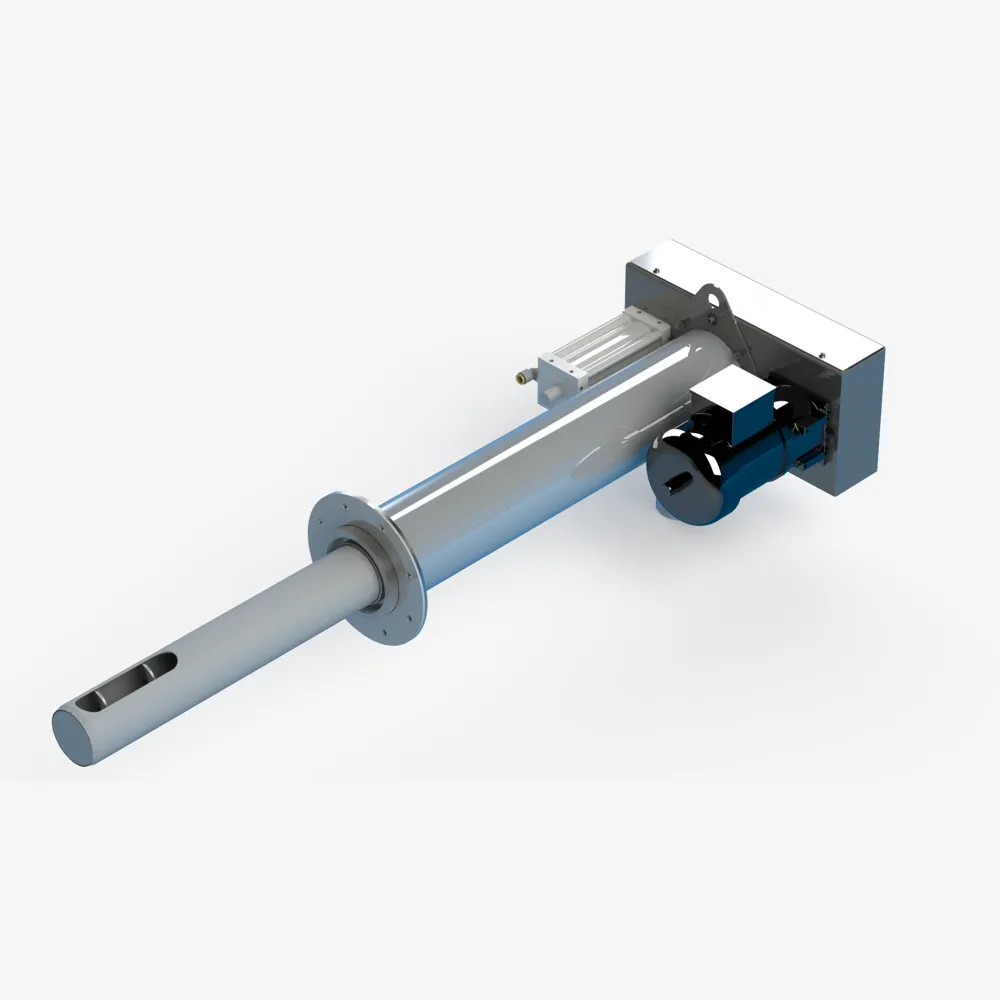

Steam Sampling System

Steam sampling is critical in a process plant because steam is a required utility for most chemical, petrochemical and refining processes. Without it, molecules don’t get cracked, reactors don’t get heated and hopes for high yielding chemical processes don’t materialize. Steam impurity may cause operational issues with turbines and other process equipment, corrosion of process components and/or scaling of metal surfaces. To mitigate these risks, analysis of process steam and condensate is an important aspect of any chemical processing or refining operation. Impurities in these systems such as silica, sodium or deviations from target pH values can wreak havoc on a plant’s operations. On-line analysis of sodium and cation conductivity is commonly performed to monitor the condition of process steam.

Sentry Controllers and Accessories

Sentry SBC Automatic Sampler Controller

- Dedicated logic control system capable of controlling any automatic sampler in the Sentry product line

- Operator-friendly user interface features both local and remote operating modes

- Customize operation to your process using standard features such as batch sampling, flow proportional sampling, flow counter based sampling, and control of the Sentry Indexing Cabinet (IC)

- Supports ModBus, CAN, and other protocols

- Custome programming available

Sentry IC Indexing Cabinet

- Multiple position indexing cabinet designed for collecting either individual or composite sample of dry bulk solids materials

- Electrically driven carousel features 8, 16, or 24 collection positions

- Controlled by a PLC; interfaces with the sampler controller

- Offered with TEFC or explosion-proof motor

- CE and ATEX compliant models available