Sistem Pengambilan Sampel

Sistem Pengambilan Sampel Sentry

Sistem Proses Pengambilan Sampel Sentry memungkinkan Anda memiliki real time data yang terkontrol untuk memantau proses Anda. Dengan ini Anda dapat membuat analisis yang cermat tentang kualitas Anda yang sangat penting dalam pemrosesan modern. Dengan mengkondisikan, mengambil sampel, dan mengukur gas, uap, cairan, slurry, padatan bubuk, atau air secara efektif di lingkungan produksi Anda. Anda dapat mengontrol proses Anda dengan percaya diri.

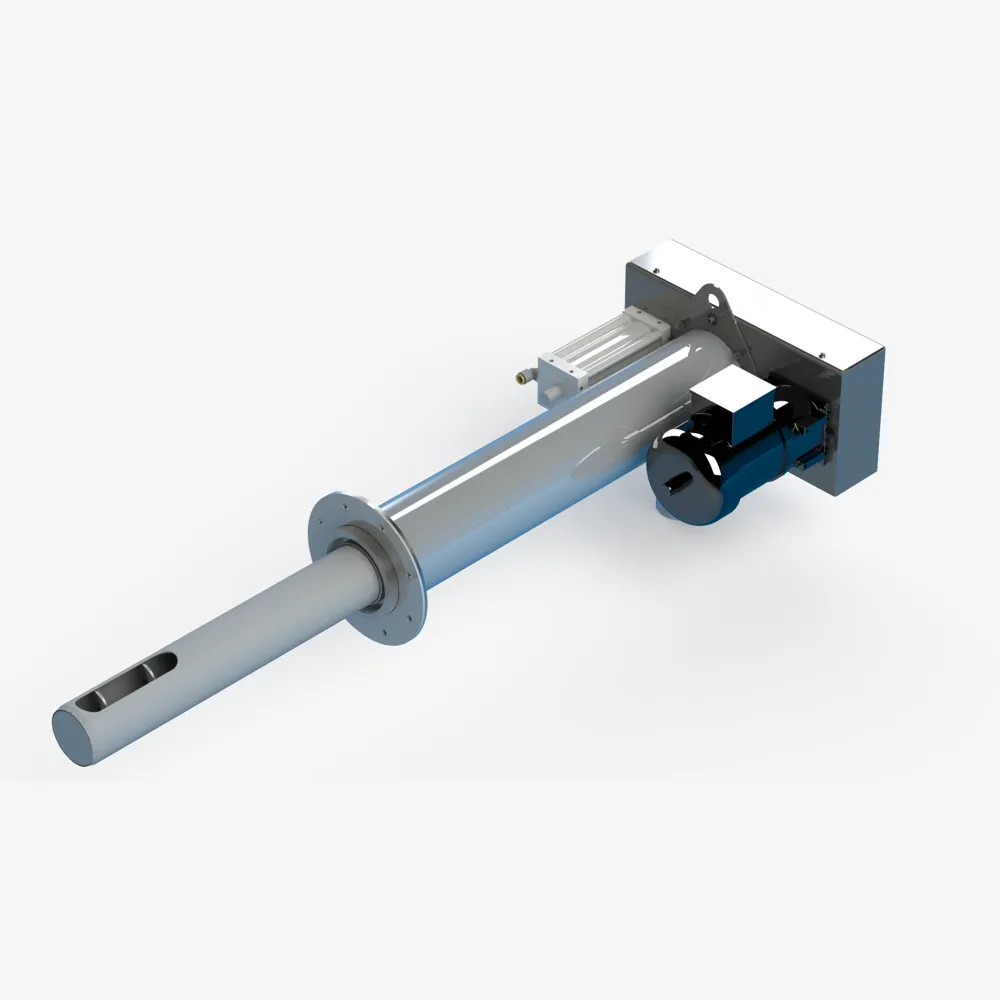

Sistem Pengambilan Sampel Uap

Sistem Pengambilan Sampel Uap sangat penting pada plant proses karena uap merupakan utilitas yang diperlukan untuk sebagian besar proses kimia, petrokimia, dan proses pemurnian. Tanpa uap, molekul tidak akan terpecah, reaktor tidak akan dipanaskan, dan harapan untuk proses kimia dengan hasil baik tidak akan terwujud. Ketidakmurnian pada uap dapat menyebabkan masalah operasional dengan turbin dan peralatan proses lainnya, korosi pada komponen proses, dan/atau pengendapan pada permukaan logam. Untuk mengurangi risiko ini, analisis uap proses dan kondensat merupakan aspek penting dari setiap operasi pemrosesan kimia atau pemurnian. Ketidakmurnian dalam sistem ini, seperti silika, natrium, atau penyimpangan dari nilai pH yang ditargetkan, dapat menyebabkan gangguan serius pada operasi plant. Analisis on-line natrium dan konduktivitas kation biasanya dilakukan untuk memantau kondisi uap proses.

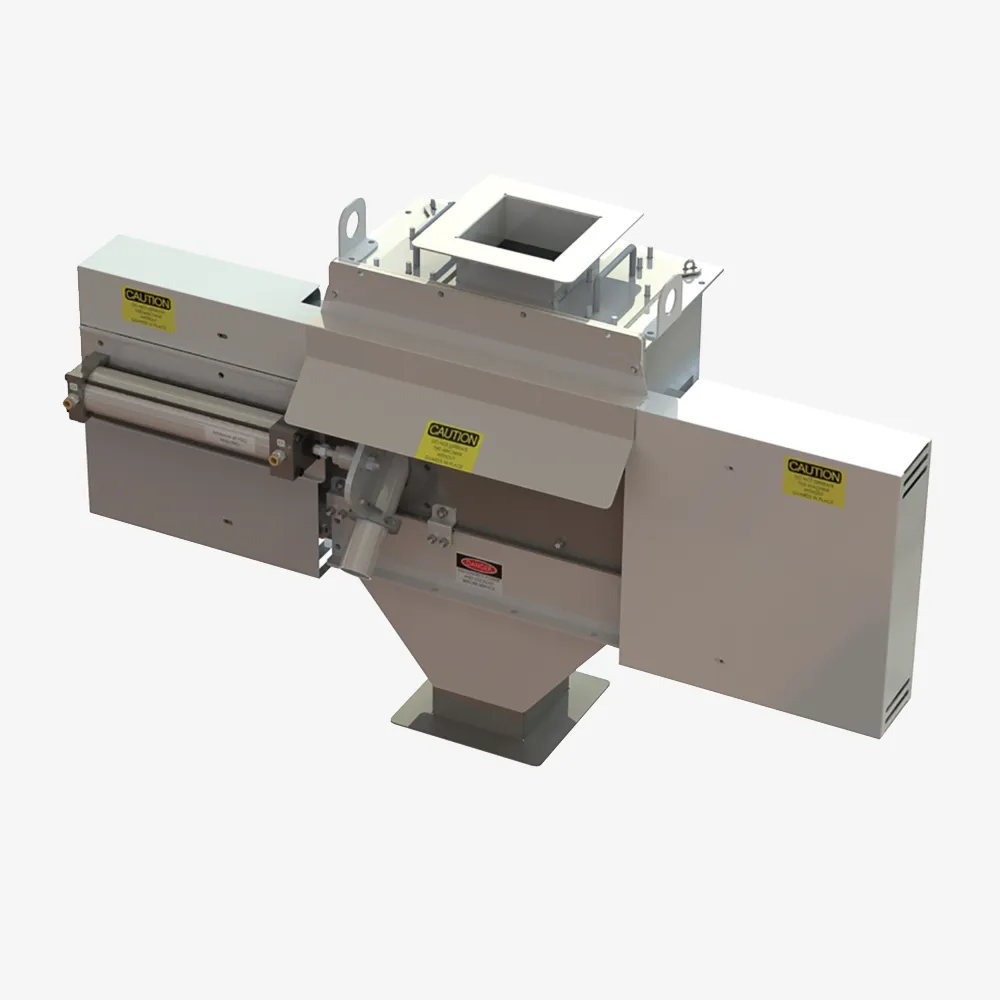

Pengambil Sampel Padatan Massal mengambil sampel biji, bubuk, butiran, pelet, dan sebagainya dengan akurat. Pilih metode pengambilan sampel Anda dari pengambil sampel cross cut, pengambil sampel point, dan pengambilan sampel variabel.

Pengendali Pengambil Sampel Sentry dan Aksesoris

Pengendali Pengambil Sampel Otomatis SBC Sentry

- Sistem kontrol logik khusus yang mampu mengkontrol setiap pengambil sampel otomatis dalam lini produk Sentry.

- Antarmuka yang mudah dimengerti operator, mendukung mode operasi lokal dan jarak jauh.

- Sesuaikan operasi dengan proses Anda seperti pengambilan sampel berbasis penghitung aliran, dan kontrol Sentry Indexing Cabinet (IC).

- Mendukung protokol ModBus, CAN, dan protokol lainnya.

- Tersedia Pemograman sesuai permintaan.

Kabinet Pengindeks IC Sentry

- Kabinet pengindeksan dengan beberapa posisi yang dirancang untuk mengumpulkan sampel individual atau gabungan dari bahan padat kering.

- Karusel yang digerakkan secara elektrik memiliki 8, 16, atau 24 posisi pengumpulan.

- Dikendalikan oleh PLC; terhubung dengan pengambil sampel controller.

- Dilengkapi dengan motor TEFC atau motor tahan ledakan.

- Tersedia model yang sesuai dengan standar CE dan ATEX.