VACUUM CONVEYING SYSTEM – PIAB

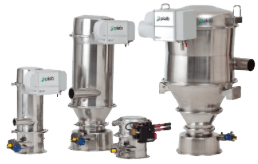

Industrial piFlow®i

DESCRIPTION

- Widely used in the general industry and sometimes chemical industry especialy harmful and hazard area

- Small foot print

- Capacity up to 4 tons/h

- Available with either an ejector driven vacuum pump or with a mechanical pump

SOLUTION

- Big Bag unloading

- Diecasting

- Feeding 3D printers

- Horizontal form-fill-seal

- Injection molding/pellet transfer

- Reclaim

- Small bag unloading

- Transfer tablet/fragile material

Industrial piFlow®f

DESCRIPTION

- A conveyor that come with food grade quality standard

- An alternative to mechanical conveyors when there is a requirement for dust free conveying or low maintenance

- Capacity up to 4 tons/h

- Description

SOLUTION

- Big Bag unloading

- Diecasting

- Feeding 3D printers

- Horizontal form-fill-seal

- Injection molding/pellet transfer

- Reclaim

- Small bag unloading

- Transfer tablet/fragile material

Industrial piFlow®t

DESCRIPTION

- A conveyor when a premium technology is needed especialy to handle tablets or fragile products in the food, nutraceutical and pharmaceutical industries

- Small foot print

- Suitable for transporting up to four milions tablets per hour

SOLUTION

- Big Bag unloading

- Diecasting

- Feeding 3D printers

- Horizontal form-fill-seal

- Injection molding/pellet transfer

- Reclaim

- Small bag unloading

- Transfer tablet/fragile material

Industrial piFlow®p

DESCRIPTION

- A conveyor when a premium technology is needed, e.g. in the food and pharmaceutical industry.

- Small foot print

- Capacity range from 2 liters batch volume up to 56 liters.

- Available with either an ejector driven vacuum pump or with a mechanical pump

SOLUTION

- Big Bag unloading

- Diecasting

- Feeding 3D printers

- Horizontal form-fill-seal

- Injection molding/pellet transfer

- Reclaim

- Small bag unloading

- Transfer tablet/fragile material