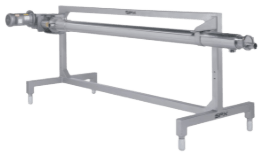

Scrapped Surface Heat Exchanger – VOTATOR

by Waukesha Cherry-Burrell

VOTATOR® II Horizontal

Votator scraped surface heat exchangers have been replacing slow, inefficient batching operations with more uniform, controllable and repeatable continuous processing.

FEATURES:

- The Votator II and the Extra Heavy Duty Votator II replace the Thermutator and standard Votator units, and is also available as a vertical unit.

- 3A, ASME,and PED Certified

- Single and Double Mechanical Seals

- Greater material choices for various applications (ceramic, carbon, silicon carbide, and tungsten carbide)

- Available in standard and narrow faces

- Ease of maintenance and lower cost of ownership

- PEEK™ Blades

- 100% PEEK™ - no filler or inserts

- Available in metal detectable version

- Integral Gear Motor Drive

- Gear drive is directly coupled to the mutator shaft eliminating the need for a secondary drive shaft and bearing block

- Overall length of heat exchanger is reduced by 20 - 25%

- Easy to maintain and self-aligning

- Available with up to 30 horsepower for handling the most viscous products

VOTATOR® II Vertical

The Votator II incorporates the most popular features of the Thermutator and Votator lines. The unique hydraulic system on the vertical unit makes inspection easy without the use of tools.

FEATURES:

The Votator Extra Heavy Duty units are designed for heating and cooling products with viscosities in the 1,000,000 centipoise range. They can be specified with concentric, eccentric or oval heat transfer tubes to provide optimum processing conditions for any product.

- 3-A, ASME and PED certified

- Concentric, eccentric, and oval tube and shaft arrangements

- Heavy duty roller bearing on non-drive product head

- High torque 17-4 ph stainless steel drive end spline

- Modified motor pedestal for use with high horsepower gear drive

- Features and design options match the availability on the Votator II

VOTATOR® II Extra Heavy Duty

The Votator Extra Heavy Duty units are designed for heating and cooling products with viscosities in the 1,000,000 centipoise range. They can be specified with concentric, eccentric or oval heat transfer tubes to provide optimum processing conditions for any product.

FEATURES:

- 3A, ASME and PED certified

- Concentric, eccentric, and oval tube and shaft arrangements

- Heavy duty roller bearing on non-drive product head

- High torque 17-4 ph stainless steel drive end spline

- Modified motor pedestal for use with high horsepower gear drive

- Features and design options match the availability on the Votator II.

4 X 120 Series

The patented Votator® 4 x 120 is designed to deliver efficient performance for lower initial investment, as well as lower maintenance cost.

FEATURES:

- 3A Approved/PED-SEP compliant

- All 316 stainless steel construction with high efficiency stainless steel heat transfer tube and optional AL6XN construction

- Available with 9 ft (0.84 m²) heat transfer area

- Horizontal units can be mounted side by side with up to 8 cylinders per frame or furnished loose for vertical mount.

- All units are suitable for steam or liquid media.

- Mechanical seal with flush connection on drive end with sleeve bearing on non-driven end

- 3 and 5 horsepower (2.2 kW - 5.5 kW) gear drives with shaft speeds of 90 and 175 rpm

- Plastic scraper blades

- Product side pressure of 200 psig (14 bar) @ 365°F (185°C); jacket pressure of 150 psig (10.5 bar) @ 365°F (185°C)

- 2-3/8" inch (60 mm) shaft diameter for particulates up to ¾" (19 mm)

- 2 inch S-Line product connections, 1½" (38mm) FPT media connections

- Self-aligning mutator shaft. No motor coupling, belts or sheaves required