CENTRIFUGAL PUMP

200S Series - for Sanitary

by Waukesha Cherry-Burrell (SPX Flow)

We take particular pride in our 200 Series centrifugal pump Line, offering the pump user the benefits of traditional quality, value and service with higher levels of performance.

FEATURES:

- 316L stainless steel volute, backplate, impeller and shaft

- Five-bladed impeller with deeper eye for improved inlet characteristics

- Modular seal design - one size fits all models

- Wide range of seal options, including standard commercial seals

- Strong JM-type motor with large bearings and strong shaft

- Base mounting options available with all sizes

- Temperature range of fluids up to 450°F (232°C)

200LR Self Priming - for Sanitary

by Waukesha Cherry-Burrell (SPX Flow)

The 200LR Series Liquid Ring Pump handles products with entrained air as well as maintaining its prime when otherpumps become air bound. This feature makes the 200LR the best choice for complete emptying of tanks and lines during normal processes or CIP.

In addition to being an excellent CIP return pump, the 200LR can run in either direction, making it possible to fill or empty tanks with the same pump.

The 200LR Series offers less overhead space needed due to both suction and discharge ports being on the front cover. This model has same seal(s) as used in 200 Series Centrifugal Pumps. Reduced noise levels. Stainless steel motor adapter is standard. JM Motor and no stub shaft eliminates need to check TIR (Total Indicated Runout). All product contact surfaces are 316L stainless steel with 32Ra finish.

C Series - for Sanitary

by Waukesha Cherry-Burrell (SPX Flow)

Versatile Waukesha C-Series Centrifugal Pumps from Waukesha Cherry-Burrell find broad application throughout sanitary and industrial processes. These rugged pumps accommodate a wide range of solids and liquids under a variety of flow conditions and deliver long service with minimum downtime.

FEATURES

- Hydraulic balancing reduces pressure at sealing surface for less wear, greater efficiency

- Easy-cleaning, open type impeller delivers smooth pumping performance

- Enlarged inlets available for larger suction lines

- Standard CIP capability

- Pump and parts are interchangeable with other C-Series brands

Combi Norm – for Non Sanitary

by Johnson Pump (SPX Flow)

This is a standard centrifugal pump that is coupled with a motor. This pump is suitable for clean and slightly contaminated liquids with flanges are according to ISO 7005 PN16. The impeller used is a closed impeller with back vanes providing axial balancing of impeller loads. Easy maintenance can be carried out with an easy back pull out method. It has outstanding hydraulic performance. Seals can be standard single seal or with balanced double mechanical seals. Single or double cartridge seals with seal support system is also available.

Combi Chem – for Non Sanitary

by Johnson Pump (SPX Flow)

CombiChem represents a range of horizontal centrifugal pumps, designed to ISO 2858 / EN 22858 (DIN 24256), suitable for handling low viscosity, clean or slightly contaminated liquids.

Pump features is standardized and modular design with flanges according to ISO 7005 PN 16. Stainless steel execution 150 lbs ANSI B 16.5 available. Outstanding hydraulic performance and high efficiency impeller. Closed impeller with back vanes providing axial balancing of impeller loads and half open impeller with wear plate and external adjustment. Easy maintenance through the Back-Pull-Out principle. Single unbalanced / balanced seals to EN 12756 (DIN 24960). Single and double cartridge seals with seal support system.

SPECIFICATIONS:

Casing: Cast iron, Nodular cast iron, Bronze, Stainless steel

Impeller: Cast iron, Bronze, Stainless steel

Max. capacity: 800 m3/h

Max. delivery head: 160 m

Max. liquid temp: 200°C

Max. pressure: 1600 kPa (16 bar)

Max. speed: 3600 rpm

Combi Prime – for Non Sanitary

by Johnson Pump (SPX Flow)

Combi Prime designed for Self-priming duty application with standard EN 733 (DIN 24255), Vertical or Horizontal. Built-in vacuum pump with external adjustment. Large air displacement capacity, shortening suction times. Flanges according to ISO 7005 PN 16. Closed impeller with back vanes providing axial balancing of impeller loads.

SPECIFICATIONS:

Casing: Cast iron, Bronze

Impeller: Cast iron, Bronze, Alu-Bronze

Max. capacity: Vertical; 800 m3/h Horizontal; 500 m3/h

Max. delivery head: 100 m

Max. liquid temp: 80°C

Max. pressure: 1000 kPa (10 bar)

Max. speed: 3600 rpm

Self-priming: Up to 8m

KGE-Self Priming – Non Sanitary

by Johnson Pump (SPX Flow)

The Johnson model KGE single stage pump is a traditional self priming pump that has been designed for Johnson since the beginning. It has a radial (semi open or closed impeller, over hung mounted on a pedestal. For easy dismantling of the pump the inlets and outlet pipes should be installed with a spacer. The drive can be clockwise or anticlockwise. This pump can be used for rugged service to move water, oils, draining buildings during excavations, extraction of water in ships, waste water, and condensate extraction. The max capacity is 100m3/hr and pressure 8 bar. Maximum water temperature is 95°C.

Combi Dirt – for Non Sanitary

by Johnson Pump (SPX Flow)

This is a robust single stage centrifugal pump for pumping fluids containing solids. CombiDirt is also capable of handling gaseous liquids and media requiring self-priming conditions. This pump uses vortex technology with open impellers to prevent clogging. The flanges is according to ISO 7005 PN16. ATEX and Self priming option is available. The impeller has back vanes to sweep solids away from the shaft sealing area. Maintenance is easy with a back pull out. The seal is single and unbalanced mechanical seal to EN 12756 (DIN 24960). Other seal options are quenched shaft seal or gland packing. This is a dry shaft design where the pumped liquid is not in contact with the shaft. The shaft is carried with a double row contact thrust bearing and cylindrical roller bearing.

Combi Bloc – for Non Sanitary

by Johnson Pump (SPX Flow)

This is a single stage closed coupled centrifugal pump produced to EN733 (DIN 24255). This pump is compact economical and has a small footprint. No shaft alignment is required and has outstanding hydraulic performance. The impeller is supplied with a high efficiency closed impeller with back vanes giving axial balancing of impeller loads. Maintenance is easy with low maintenance and installation is easy without a baseplate. ATEX certification is available and vertical arrangement is possible. The standard seal is mechanical according to EN12756 (DIN 24690). This pump is suitable for clean, fluids with low viscosity or slightly contaminated fluids. The casing is cast iron, bronze or stainless steel. The impeller is cast iron, bronze or stainless. The max capacity is 850m3/hr at 10 bar.

SPECIFICATIONS:

Casing: Cast iron, Bronze, Stainless steel

Impeller: Cast iron, Bronze, Stainless steel

Max. capacity: 850 m3/h

Max. delivery head: 105 m

Max. liquid temp: 120°C

Max. pressure: 1000 kPa (10 bar)

Max. speed: 3600 rpm

Combi Therm – for Non Sanitary

by Johnson Pump (SPX Flow)

CombiTherm ensures uniform process temperatures while keeping damaging heat away from seal faces and bearings. CombiTherm is designed to require no external cooling when working within the given parameters. The throttle bush, journal bearing and seal placement reduce circulation and temperature along the pump length. This greatly reduces the temperature at the seal face and bearings.

SPECIFICATIONS:

Casing: Nodular cast iron

Impeller: Cast iron, Stainless steel

Max. capacity: 350 m3/h / 1541GPM [50Hz], 400m3/h / 1761GPM [60Hz]

Max. delivery head: 110m / 361ft [50Hz], 160m / 525ft [60Hz]

Max. liquid temp: Thermal oil 350°C / 662°F, Hot water 190C / 374F

Max. pressure: 16bar / 232psi

Max. speed: 3600 rpm

Combi Mag- Magnetic Drive Pump - for Non Sanitary

by Johnson Pump (SPX Flow)

Centrifugal pumps are driven by a motor through a shaft which have to penetrate into the pump chamber. In order to keep the products inside, a seal is needed. This seal often wears off and the product leaks. This is problematic if the product leaked is poisonous or is flammable. Arasains Indonesia supplies the Johnson CombiMag, a centrifugal pump driven by a magnetic coupling. This makes the pump 100% leak free with a long life cycle and reduced maintenance cost. This pump uses the Johnson famous high efficiency impeller. It is suitable for slightly contaminated liquids without abrasive or magnetic particles. Maintenance is easy with back pull out principle. Magnets used are Samarium Cobalt high performance magnets. The containment can is made of Hastelloy for limited eddy current losses. Heating jackets can be supplied. Lubrication can be specified for oil or grease. Temperature monitoring with PT 100 are available. The pump impeller has liquid lubricated silicon carbide internal bearings with hardened wear plate.

SPECIFICATIONS:

Casing: Cast iron, Nodular cast iron, Stainless steel, Stainless steel alloys, Nickel based alloys, Duplex

Impeller: Cast iron, Bronze, Stainless steel, Stainless steel alloys, Nickel based alloys, Duplex

Max. capacity: 550 m3/h

Max. head: 160 m

Max. pressure: 1600 kPa (16 bar)

Viscosity 0.3 mPas - 150 mPas

Max. speed: 3600 rpm

Liquid temp: -50 up to 300°C

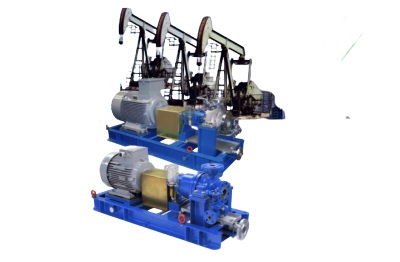

Heavy Duty Pump for Oil and Gas

by Johnson Pump (SPX Flow)

This is a heavy duty pump designed for the oil and gas industry, refineries and general industries. It suitable for clean low viscosity and slightly contaminated liquids. The CombiPro is a center line mounted end suction overhung single stage process pump. The design specifications are to API 610 and seal chamber to API 682. The pump casing and cover has metal to metal fit with a fully confined controlled compression wound gasket. The pump comes with a fully integrated design, pump, motor, baseplate and accessories. The impeller is dynamically balanced with either a closed or half open impeller type. Flange are according to ISO 7005 PN50. /300lbs, ANSI B 16.5 or ISO 7005 PN20/150lbs ANSI B 16.5. ATEX certification is available. Bearing housing cooling is an option. A magnetic drive version according to API 685 can be made upon request. Maximum capacity is 350m3/hr at 35bar. The maximum liquid temperature is 350°C. Material of construction is cast iron, nodular cast iron, bronze, stainless steel, carbon steel and 13% Cr steel.

Multi Stage - for Non Sanitary

by Johnson Pump (SPX Flow)

Johnson multistage pumps include a series of pumps in vertical or horizontal execution. The pumps can be supplied self-priming. The material of construction of the body and impeller is cast iron or bronze. The maximum capacity is 100m3/hr at 35 bar head. The pump consist of an inlet and outlet casing and a number of stages in between. Each stage has a radial diffuser and a matching impeller. The flanges are built according to DIN 2535 ND40. Shaft seal is either by mechanical seals or gland packing. This pump is rigid & reliable construction, low maintenance cost, and high pump efficiency.

SPECIFICATIONS:

Casing: Cast iron, Bronze - only the MCH-versions

Impeller: Cast iron, Bronze

Max. capacity: 100 m3/h (440 GPM)

Max. delivery head: 340 m (1120 ft)

Max. operating pressure: 4000 kPa (40 bar)

Max. speed: 3600 rpm (40 bar) (580 psi)

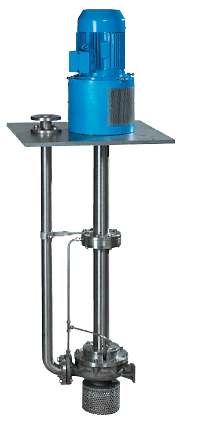

Sump Pump for Oil and Gas

by Johnson Pump (SPX Flow)

This pump is designed for lifting fluids from below ground level or from a sump. It is suitable for clean fluids or slightly contaminated liquids such as effluent, cleaning products, chemicals and hydrocarbon. The design standard used is API 610/682 especially for the petroleum industries. A magnetically coupled version is available. The maximum depth is 10 m. The impeller used is closed impeller with back vanes providing balancing of axial loads. A half open impeller with wear plates can be available. The standard sealing is oil seals but mechanical seals or gland packing is available. A vapor tight rectangular or circular mounting plate or pressurized design is optional. Motors can be standard IEC or ATEX design. Maximum capacity is 1500m3/hr and pressure 35 bar. Maximum liquid temperature is 160 C.

To Get More Information

Don't Hesitate to Contact Us

Company Address

Rukan Kirana Boutique Office

Blok F3 no 12, Boulevard Raya No.1 Kelapa Gading. Jakarta Utara

Indonesia, 14240

Contact

+6221 4585 8833

info@arasains.co.id

Quick Link

Product Link

Copyright (c) 2021 PT Arasains. All Right Reserved