HYGIENE MONITORING

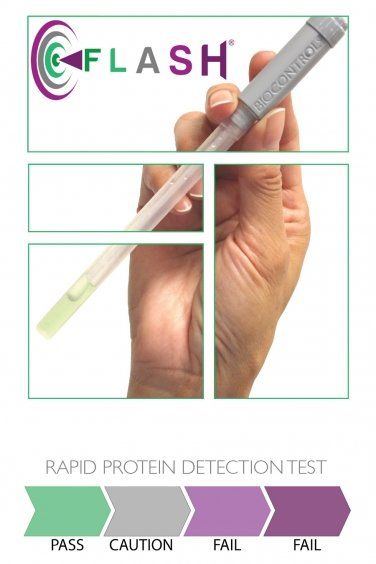

Surface Protein Residue Test - FLASH® Allergen

Food production surfaces are often contaminated with protein especially those associated with meat processing. Merck Biocontrol Indonesia introduces FLASH® protein residue test kits to measure your cleaning effectiveness. This kit swabs the food preparation surfaces and detect if they have been effectively removed by the cleaning procedure.

Overview

FLASH® is a room temperature-incubated total protein test that rapidly detects protein residues left on food contact surfaces after cleaning. Used as part of HACCP allergen control program, FLASH® supports process verification requirements that ensure cleaning methods, validated to effectively remove allergens, are consistently applied. FLASH® has been tested against common allergenic proteins including soy flour, gluten flour, milk powder, egg powder, peanut butter, roasted almonds, raw fish (cod), and raw shrimp.

Benefits:

- Easy to analysis with clear color interpretation

- Fast time to result, within 10 minutes

- Sensitivity detection down to 20 μg

- No instrumentation is required

- Can be used by all personnel without the need for extensive training

Surface Hygiene Test - Lightning MVP® ICON Luminometer

A clean production plant is the first prerequisite for manufacturing of safe food and to uphold your brand. Testing ATP luminometer will permit pre operation inspection questions like “Is it safe to start the plant”. The detection of ATP through bioluminescence is a well-established and widely used indicator of surface hygiene and cleaning efficacy in food processing. Merck Biocontrol Indonesia introduces a new re-modelled and more powerful instrument for measuring surface hygiene called the MVP ICON®. This is a next generation model designed with better sensitivity combined with a user-friendly powerful program with management capabilities for you to manage your HACCP, ISO audits and to track the cleanliness of your production facilities.

Overview

The MVP ICON® is a pioneering system that measures and records the amount of ATP on the surface of the plant production surfaces. ATP is a molecule for energy storage used by all living cells and it is left over from the previous production cycle due to inadequate cleaning. A swab picks up this molecule and it is reacted with an enzyme luciferin/luciferase to produce light. This light is measured by a photometer and is proportional to the degree of contamination. ATP is used as a measure of plant cleanliness by all the leading food manufacturers in the world. The results are available real time and allows quick decision and corrective action unlike plate counts which gives results in at least 24 hours. The MVP ICON can be used with two types of sampling device; a surface swab and a liquid sampling device. The surface swab offers a one step, one hand driven activation, freeing the operator to perform other operations. All reagents are contained within the device. The liquid sampling device allows the operator to collect and measure the ATP content of liquid samples like CIP rinse water directly from the source without pipetting or use of a sampling container.

Features and Benefits:

Advanced Instrument Design - Next Generation User Interface

Touch screen application even with gloves. Vibrant color display makes the screen easy to read under all lighting conditions. Lightweight with ergonomic design.

New Beneficial Features – Beyond Innovation

Intuitive navigation makes locating test points easier. Sample plan feature allows users to assign one or multiple test points to the same sample plan, creating sampling organization. Re-test feature allows users to re-test failed test points to demonstrate that the effective cleaning has taken place.

Powerful Software – Take the Guesswork Out of Hygiene Monitor

Automated data analysis for analyzing and interpreting results. Real-time reporting of key metrics allows users to take immediate and corrective action. Customizable detailed reports are generated, helping to comply with HACCP and GMP programs.

Multi Variable Parameters - One Instrument, Does It All!

One instrument able to measures multiple keys of quality indicators such as, ATP, pH, temperature, and conductivity/concentration.

Superior Sampling Swab Design – Promotes Accuracy and Reproducibility

Proprietary controlled reagent flow design offers superior accuracy and reproducibility, eliminating variation in operator′s collection technique. Proprietary neutralizing buffer minimizes potential interference from sanitizers. Lyophilized reagents allowing stable storage even in the room temperature.

Frequently Asked Questions

-

Do you need to calibrate the icon to the results for each factory you use?

No the scale used by ICON has been correlated for use in all factories and results can be used and compared interfactory.

-

Does the ICON MVP meter measure bacteria?

The ICON MVP measures bacteria on the swapped surfaces as well as any food residue on it. It does not differentiate between bacteria and food residue.

-

What is the point of using the MVP icon?

The MVP ICON will allow you to tell whether you can start production safely. After your last cleaning, bacteria feed on the food residues left behind by inadequate cleaning and they grow and contaminate your food.

-

How long does a measurement take?

It takes about 1 minute for swapping the food production surface and another to read the results.

To Get More Information

Don't Hesitate to Contact Us

Company Address

Rukan Kirana Boutique Office

Blok F3 no 12, Boulevard Raya No.1 Kelapa Gading. Jakarta Utara

Indonesia, 14240

Contact

+6221 4585 8833

info@arasains.co.id

Quick Link

Product Link

Copyright (c) 2021 PT Arasains. All Right Reserved